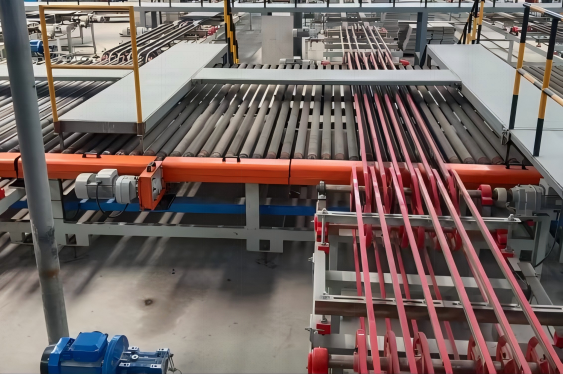

The kiln in and out machine is the connecting equipment for the green body to enter and exit the drying kiln. It is independently designed according to the product specifications and output. The transmission methods of the kiln in and out machine are divided into two categories. According to the different products, the transmission methods are different, which are divided into helical gear transmission and synchronous belt transmission.

The kiln in and out machine is the connecting equipment for the green body to enter and exit the drying kiln. The length, width, height, roller size and transmission mode, motor segmentation and number of motors of the kiln in and out machine are determined according to the specifications, number of layers, product specifications and output of the drying kiln. The rationality of the parameters of the kiln in and out machine involves the smooth and stable operation of the green body in and out of the drying kiln, and whether the output can meet the design requirements. The drying kiln has different numbers of layers and configurations. Relevant auxiliary equipment must be configured as required, and space for thermal expansion and contraction of the drying kiln and production capacity matching requirements of relevant auxiliary equipment must be reserved. The electronic control is segmented by the PLC program to link the upper and lower processes.